Researchers at the Indian Institute of Technology (IIT) Mandi have developed an innovative, eco-friendly composite material designed for Electromagnetic Interference (EMI) shielding. This composite blends kenaf fiber and High-Density Polyethylene (HDPE) with carbon nanotubes, providing superior EMI shielding properties while being recyclable and biodegradable.

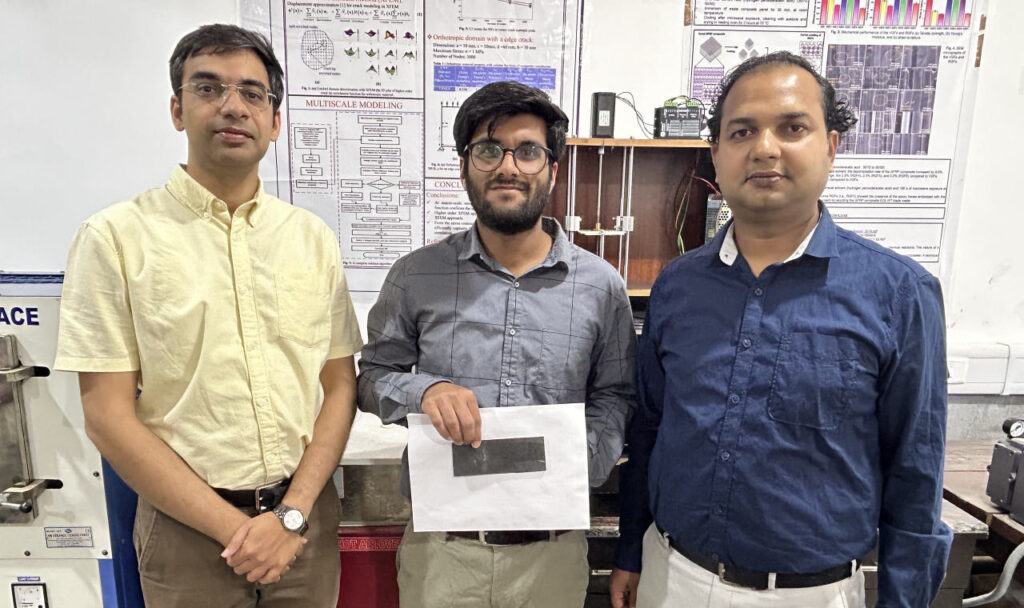

The research team, led by Dr. Himanshu Pathak and Dr. Sunny Zafar, alongside their colleagues from the School of Mechanical and Materials Engineering at IIT Mandi and Dr. Siddharth Suman from VTT Technical Research Centre of Finland, worked on this project to address the escalating problem of EMI. EMI can disrupt electronic systems across various industries, including radar systems, military controls, and networking infrastructure, necessitating effective shielding solutions.

Their eco-friendly composite incorporates kenaf fiber, known for its strength and low density, which serves as an optimal reinforcement material. This natural fiber enhances the mechanical properties of the composite while significantly reducing its environmental impact. HDPE, a widely used recyclable plastic, contributes to the composite’s sustainability.

To achieve the necessary electrical conductivity for EMI shielding, the researchers added carbon nanotubes to the composite. The final blend, consisting of 16% kenaf fiber and 5% carbon nanotubes, exhibited remarkable EMI shielding effectiveness, exceeding 30 dB, alongside excellent mechanical strength.

“Cultivating a sustainable future demands innovation that enhances performance while minimizing environmental impact. Our work in developing eco-friendly EMI shielding materials combines technological advancement with ecological responsibility,” stated Dr. Himanshu Pathak.

Traditional EMI shielding materials have typically relied on metals, which come with drawbacks such as high weight, limited flexibility, and susceptibility to corrosion. The new plastic-composite material developed by the IIT Mandi team addresses these issues with its lightweight, flexible, and chemically resistant properties, making it suitable for a wide range of applications, from electronic equipment casings to unmanned aerial vehicles (UAVs).

“The developed composite holds immense promise for real-world applications, ranging from electronic equipment casing to overhead bins and UAVs. The composite’s versatility and sustainability make it an asset in addressing contemporary challenges while promoting environmental responsibility,” said Dr. Sunny Zafar.

This innovative composite material represents a significant step forward in combining technological advancement with ecological sustainability, offering a practical solution to the growing issue of EMI while aligning with environmental goals.