As stubble burning continues to choke North India during harvest seasons, researchers from Punjab Engineering College (PEC) have introduced an innovative solution. By converting paddy straw, rice husk, and sugarcane bagasse into biodegradable composites through a chemical-free process, they offer a sustainable alternative to plastic while addressing one of the region’s most persistent environmental challenges.

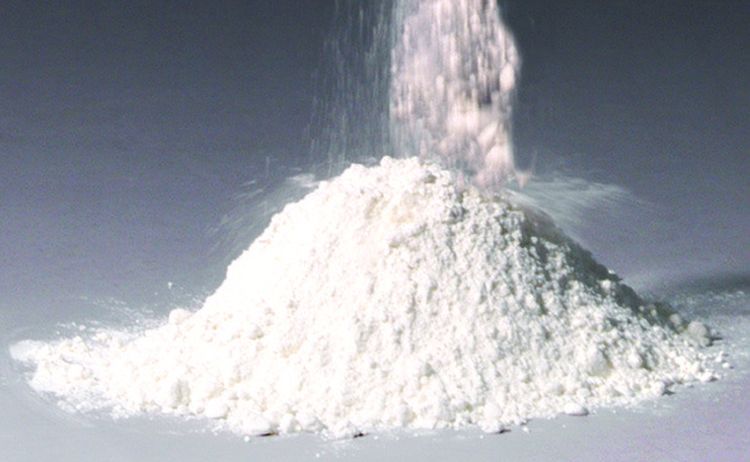

The research team, led by Prof. Sarbjit Singh and scholar Vikas Yadav, uses natural ingredients like reetha for cleaning and neem for preventing fungal growth. The resulting composite material meets stringent American Society for Testing and Materials (ASTM) standards and is suitable for manufacturing items like pens, which decompose quickly after disposal.

Tackling North India’s Stubble Burning Crisis

Stubble burning has long plagued northern India, particularly in states like Punjab, Haryana, and Uttar Pradesh, contributing significantly to air pollution. Farmers, constrained by time and resources, often burn paddy residue to prepare fields for the next crop cycle, releasing harmful pollutants like particulate matter and greenhouse gases.

Despite government interventions, such as promoting happy seeders and bio-decomposers, the practice remains widespread, especially in rural areas where awareness and access to alternatives are limited. This contributes to hazardous air quality levels during the winter months, with cities across North India frequently ranking among the most polluted in the world.

Turning Waste into Wealth

The PEC innovation could provide a dual benefit: reducing pollution from crop residue burning and addressing the problem of plastic waste. The composite material, made by mixing bagasse with polylactic acid (a biodegradable polymer derived from corn), offers a sustainable alternative to plastic in non-durable items like pens.

“A pen made from this composite decomposes naturally, unlike conventional plastic pens that linger in landfills,” explained Prof. Singh. Vikas Yadav added that if industries adopt this process, it could create a demand for crop residues, giving farmers an economic incentive to sell their stubble instead of burning it.

A Solution for the Entire Region

The potential of this innovation goes beyond Punjab. If adopted across North India, where stubble burning is a major issue, it could significantly reduce pollution levels. The creation of an economic value chain around crop residues would not only help the environment but also provide farmers with an additional source of income.

Governments and industries alike need to step forward to scale this solution, integrating it into broader initiatives to tackle pollution and promote sustainable practices. As the region grapples with worsening air quality each year, adopting such eco-friendly innovations could be a critical step towards a cleaner, healthier future.

This research, published in Industrial Crops and Products and Science of the Total Environment, showcases how science and innovation can offer practical, scalable solutions to some of North India’s most pressing environmental challenges.